ELECTRONIC MANUFACTURING SERVICES

Spectrum Advanced Manufacturing Technologies, Inc. was founded in 1997 to provide quick-turn product development and manufacturing services to the aerospace, medical, industrial and commercial marketplaces.

Our goal is to build long lasting relationships with our customers based upon our exceptional team of engineering and manufacturing talent, and to help solve challenges through innovative and cost-effective ideas with commitment to quality.

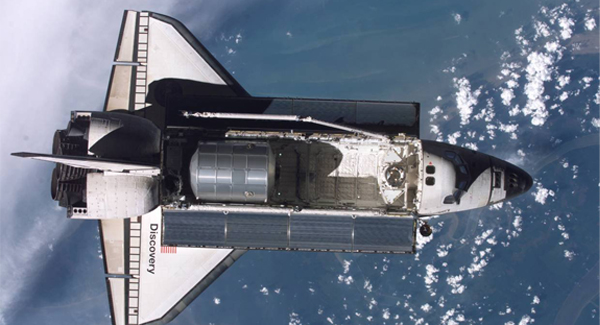

Spaceflight / Spacecraft

SPECTRUM has supported many NASA spacecraft and programs since our founding in 1997. We maintain in-house Level B Instructors for manufacturing standards.

Military / Aerospace

HI-REL ELECTRONIC MANUFACTURING SERVICES - Circuit Card Assembly Cable/Harness Manufacturing Quick-Turn, Prototype to Production

Medical

We are advancing technology through manufacturing in multiple fields of medicine, developing a growing world of medical products.

Commercial / Industrial

Our corporate mission is to provide cost-effective and timely new product development and manufacturing services to large and small companies and Government entities.

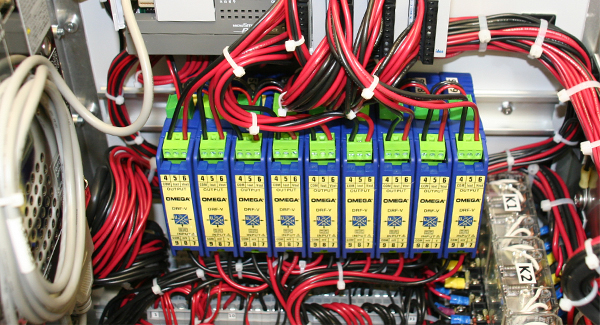

Cable / System Integration

Complex Cable and Harness Manufacturing; Satellite Bus, Instrumentation; Unit/Box Builds, Chassis Assembly, EGSE; Thermo-Vac Chamber Interfaces; IPC/WHMA-A-620 or NASA-STD-8739

Spectrum

Spectrum