Automated Optical Inspection and X-Ray

Automated Optical Inspection (AOI) provides a first level of confidence in correct component placement, orientation, and alignment. Our Mirtec and Mechatronic Systems AOI collect statistical data to identify top defects and provide real-time feedback for process tuning. SPC data collection is analyzed for process improvements to incorporate on follow-on builds.

100% visual inspection of solder joint integrity is still utilized on all assemblies. The AOI systems are used as an adjunct to quality inspectors, where inspectors can now focus on more critical points requiring human disposition.

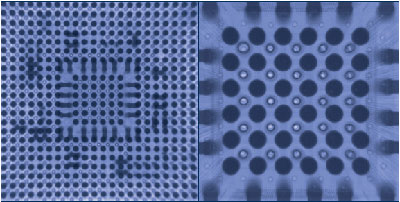

Bottom terminated components/Plated through hole fill are inspected using a Scienscope X-Scope 6000 x-ray system. The 130kV source also provides flip chip and encapsulated component inspection, viewing of inner layer registration, and through hole plating inspection.

BGA Inspection/Registration

Spectrum

Spectrum